Tower Microphone TM20

The ultrasonic tower microphone

with test signal speaker

- Knowles FG - Microphone capsule

- 40kHz test signal speaker

- Microphone heating

- Approximate input-referred self-noise level (bandwidth: 30-50 kHz): 26 dB SPL

- Approximate sensitivity: 500mV / Pa

- Power supply: 5V / 25mA provided by UltraSoundGate xx16Hnbm

- Connector: male XLR-5 plug

- ∅ 20mm / Length 55mm

- Required mounting hole ∅: 22mm

- M3 femal thread for mounting

- Cable length: 3m

- TM20 - Mounting Kit for hole mounting in tower walls and Magnetic Bracket optionally available

Tower Microphone

TM20

excl. VAT & shipping

TM20

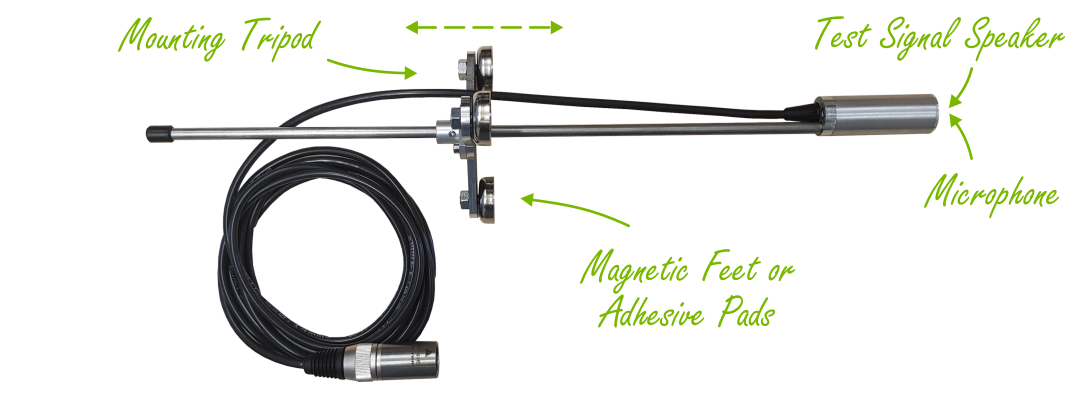

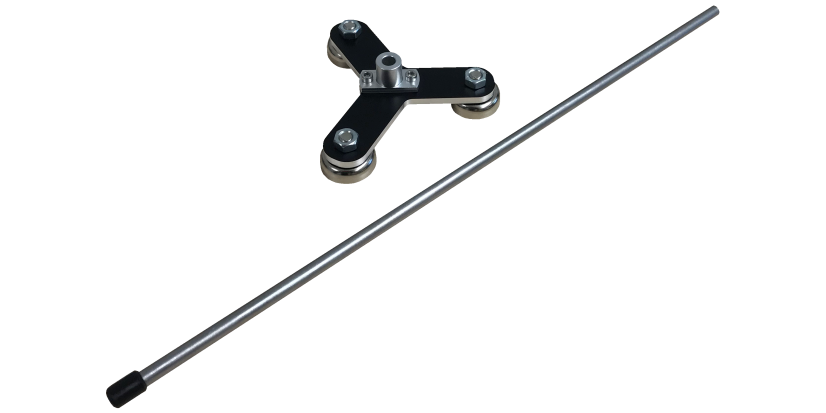

Mounting

Kit

excl. VAT & shipping

TM20

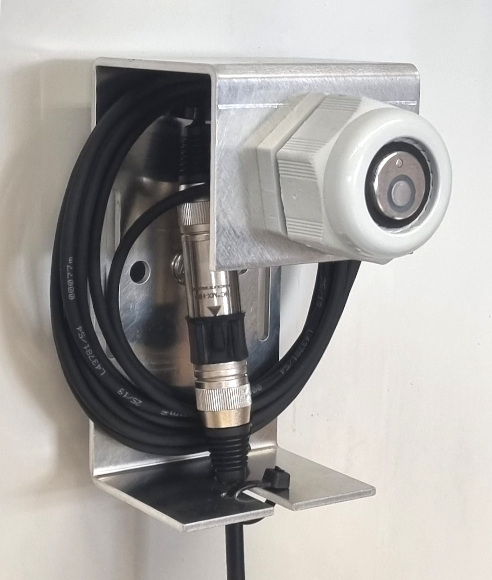

Magnetic Bracket

excl. VAT & shipping

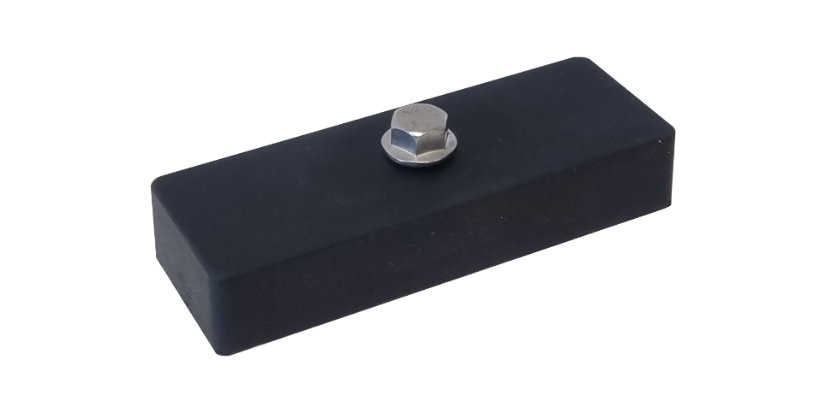

Extra Magnet for Magnetic Bracket

excl. VAT & shipping

TM20

Foam

Windscreen

excl. VAT & shipping

The electret ultrasonic tower microphone TM20, as well as the TM10, were both specially designed for mounting in the tower wall of large wind turbines for the qualitative detection of bat activity at the level of the lower rotor tips. While the focus of the tower microphone TM10 was on the smallest possible diameter, the TM20 includes a 40kHz test signal speaker in addition to the microphone. As already known from the microphone discs for nacelles, this speaker is used to play a daily 40kHz test tone for checking and logging the microphone sensitivity during a continuous log-term monitoring. With a microphone diameter of only 20mm, the required diameter of the mounting hole for the TM20 is with 22mm still extremely small. For mounting in the tower wall the optional TM20 - Mounting-Kit is available. The tripod of the Mounting-Kit slides along a rod, which is fixed to the microphone. Thus, the microphone can be easily fixed in tower walls with different wall thicknesses up to 450mm and allows a defined positioning of the microphone tip. The tripod is mounted on the tower inner wall using either magnetic feet, adhesive pads or screws (Drilling Plan - TM20). To prevent the ingress of rainwater through the mounting hole it can be drilled slightly sloping into the tower wall. Alternatively, the TM20 tower microphone can also be attached to the outside of steel towers without drilling, using the also optional Magnetic Bracket. It has a standard holding force of 70kg, which can be doubled by an additional magnet. To increase the reliability of the microphone in adverse weather conditions, the TM20 integrates a microphone heater, which reduces condensation on the microphone. Due to the M3 femal thread on the back of the microphone, the microphone is also ideal for alternative measuring situations, such as on measuring masts, in addition to the use in the tower of wind turbines. Like all other of our microphones, the TM20 is of course compatible with all BATmode systems and therefore also with the UltraSoundGate 116Hnbm and 416Hnbm from Avisoft Bioacoustics.

Notes:

In order to avoid time-consuming and costly drilling of the mounting hole when the turbine is already built-up, it is advisable to contact the wind turbine manufacturer before the wind turbine is delivered. Thus, a corresponding hole can already be considered in the manufacturing process.

To reduce electromagnetic interferences, we recommend to place the BATbox with the detection system as close as possible to the microphone and as far away as possible from interference sources such as power and control cables. For this the microphone is delivered with a 3m connection cable. In principle, it is also possible to install the BATbox on the tower base and to use an up to 150m extended microphone cable. However, this may cause a significant reduction in recording quality.